LSR Injection, Liquid Silicone Rubber

LSR Injection

Founded in 1950, Top Tech Silicone is one of Top Clean Packaging group subsidiary and became a pioneer in the injection of Liquid Silicone part (LSR) in Italy for a wide variety of industries.

Today the company develops and manufactures product and components outside and in cleanrooms for several industrial applications such as:

Specialist in liquid silicone injection (LSR)

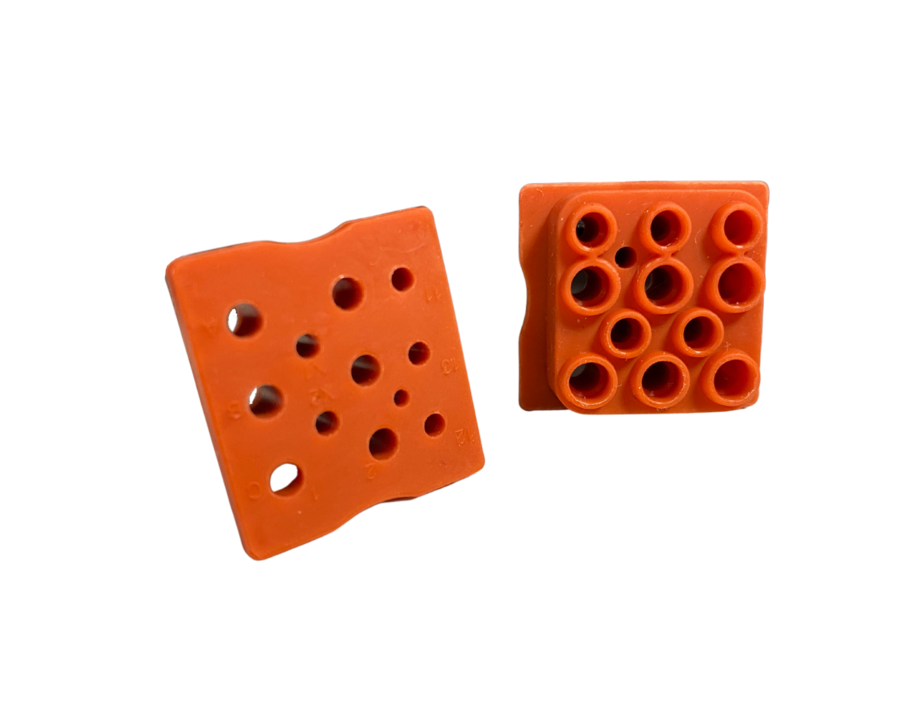

Injection of silicone parts

- Parts weight from 0,5 grams to 350 grams

- Thickness from 0,25mm

Molded raw materials

- Standard Silicone Range

- From 3 to 80 SHA

- Self lubricating

- Self adhesive and fluorolisicone

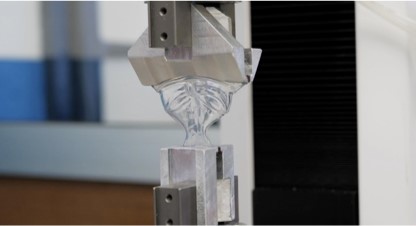

Overmolding and 2K injection

- Thermoplastics

- Metal insert

- Bi-materials

Control of chemical adhesion

LSR injection, HCR injection and compression

Small to large series of parts

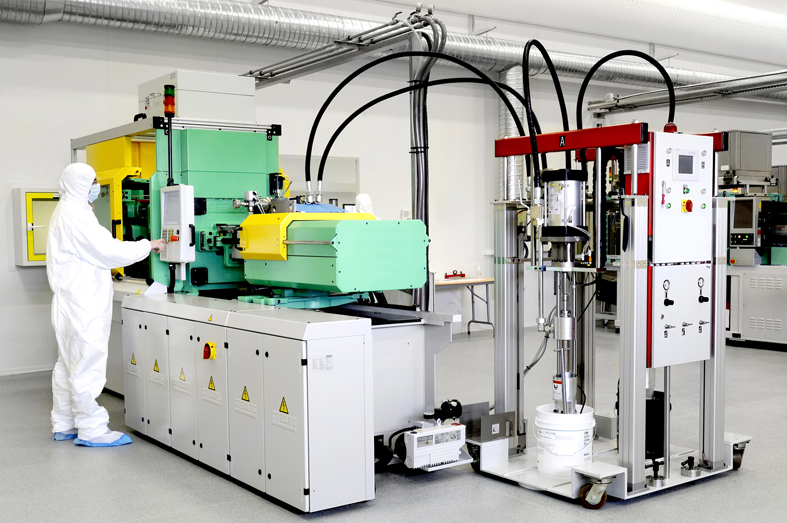

Our environments

- 1500 square metres including clean rooms

- Electric Press Park

- 6 axis robots

- Oven outisde and in cleanroom

- Silicone pad printing and cutting

Our quality means

Compliance management by our quality teams

- Development

- Industrialization

- Production

Control of validation processes

- Process capability and SPC

- Process FMEA

- R&R

- DOE

- IQ / OQ / PQ

Certifications

- ISO 9001 & ISO 13485